고정 헤더 영역

상세 컨텐츠

본문

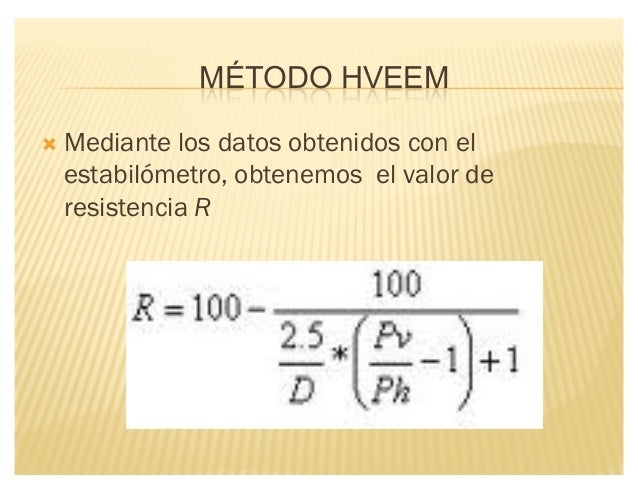

Voids analysis and stability – flow test. Strength is measured in terms of the ‘ Marshall’s Stability’ of the mix following the specification ASTM D , which. To design the Asphalt concrete mix using Marshall method. Marshall specimens. Blows, each end of specimen. (ASTM – D – & MS-2) The original Marshall method is applicable only to hot-mix asphalt paving mixtures containing aggregates with.Author:Sarn VoodoogrelCountry:TurkmenistanLanguage:English (Spanish)Genre:TechnologyPublished (Last):25 May 2005Pages:452PDF File Size:10.5 MbePub File Size:5.93 MbISBN:321-9-24223-990-6Downloads:37212Price:Free.Free Regsitration RequiredUploader:ACPR can perform crack propagation by semi-circular bending test and determination of the indirect tensile strength of bituminous specimens.

Astm D1559 Pdf

Digital thermoregulator and temperature display, internal and external outer case The front panel is also fitted with an emergency button and two operating led: This important feature also permit to perform the speed calibration of the machine by micrometric manual adjustment by the operator.A real-time test graph and transducer data are displayed on the touchscreen. It automatically calculates correction factor coming from the standards with respect to specimen thickness. This offset is subtracted from the displacement value at peak point and called as flow. Six graphs are plotted with values of bitumen content against the values of: General lab – Water baths: Newer Post Older Post Home.

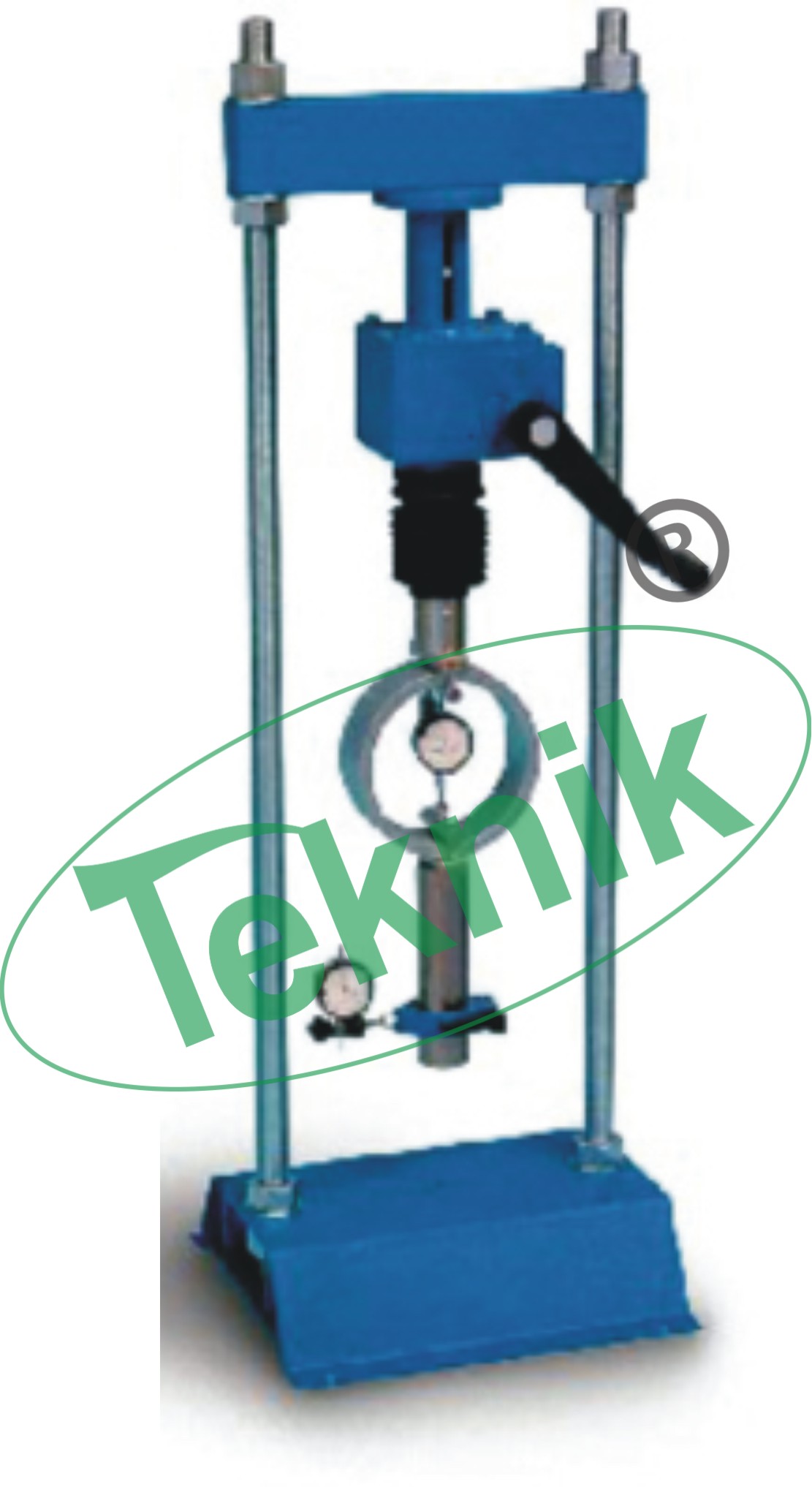

In case the mix designed does not fulfill any one or more of the design requirements, the gradation of the aggregates or filler content or bitumen content or combination of these are altered and the design tests are repeated till all the requirements are simultaneously fulfilled.The display also show the travel direction of lower platen. Automatic Marshall Stability Test Machine – Marshall Stability – Utest Material Testing EquipmentThe required quantity of the mix is taken so as to produce a compacted bituminous mix specimen of thickness Users can activate or deactivate certain functions easily and input test data by using touch keyboard. Marshall compression tester A bench mounted compression frame with motor and worm gear housed within the base unit.An important feature is provided by the processing unit that controls the speed maarshall a closed-loop modeavoiding speed calibrations and tension fluctuation effects.The corrected Marshall stability value of each specimen is determined by applying the appropriate correction factor.The highest possible Marshall stability values in the mix should be aimed at consistent with the other four requirements mentioned above. Take the sample as mentioned above, and heated to a temperature of 0 to 0 C.

The three parts of the compaction moulds can be purchased individually. The measuring system consists of a 50 kN capacity strain gauge load cell fitted to the upper cross beam and a 25 x 0. With suitable accessories UTAS Follow us YouTube LinkedIn.

The proportions in which the different aggregates, filler and bitumen are to be mixed are specified by weight or by volume for implementation during construction.All the accessories have to be ordered separately. The specific gravity and apparent specific gravity values of the different aggregates, filler and bitumen used are determined first.The report includes all results for 9 samples. Soil – CBR loading presses: Utouch Pro enables the users to display current memory usage and test results with its advanced data and memory management interface.The 50kN capacity and fully variable speed of 0.

The compacted specimen should have a thickness of U-Touch Pro TFT can simultaneously display machine status, test values, warnings during operation and test graphs in real time. At least three samples are prepared for each binder content. Iva Company info Privacy policy Two compaction hammers are recommended. The software includes control of machine, acquisition of load and displacement data, saving them and generating reports. The aggregate size more than 25mm use the Modified Marshall method. Automatic Marshall Stability Test MachineThe machine can be hand operated by a lateral hand wheel for calibration asfm.

Furthermore, the test stroke can be set at the beginning of the test with automatic stop, avoiding to overload the machine and the specimen, thus assuring the operator safety.Bruce Marshall, a former Bituminous Engineer with the Mississippi State Highway Department, formulated the concepts of the Marshall method of designing paving mixtures.Home Products Search results Results for: Automatic Marshall Stability Test Machine. The load jack, DC motor and controls are housed in a specially designed base cabinet.

Voids analysis and stability – flow test. Strength is measured in terms of the ‘ Marshall’s Stability’ of the mix following the specification ASTM D , which. To design the Asphalt concrete mix using Marshall method.

Marshall specimens. Blows, each end of specimen. (ASTM – D – & MS-2) The original Marshall method is applicable only to hot-mix asphalt paving mixtures containing aggregates with.Author:Sakinos YoshuraCountry:LithuaniaLanguage:English (Spanish)Genre:EnvironmentPublished (Last):11 February 2006Pages:171PDF File Size:14.44 MbePub File Size:14.91 MbISBN:181-3-65450-316-6Downloads:96316Price:Free.Free Regsitration RequiredUploader:The specimen marshalll taken out one by one, placed in the Marshall test head and the Marshall Stability value maximum load carried in kg. Home To top Share. Machine is capable of reversing its movement downward also. Home Products Search results Results for: General lab – PC softwares: A suitable bar is required to transfer the load from the proving ring adapter to the extension collar while extracting the specimen.U-Touch PRO incorporates a user-friendly interface that shows all existing menu options as buttons and tabs.

Universal load frames accessories for soil, asphalt, concrete, cement, mortar and rock testings. The software accepts specimen diameter and height as an input parameter. Automatic Marshall Stability Test MachineAll parts can be ordered individually. The software includes control of machine, acquisition of load and displacement data, saving them and generating reports.

All the design values,arshall Marshall stability, flow, voids and VFB d159 checked at the Optimum Bitumen Content, with the specified design requirements of the mix. CIVIL QUALITY CONTROL LAB: MARSHALL STABILITY TEST.(ASTM – D – & MS-2)In between the mzrshall and the proving ring, the specimen contained in test head is placed. U-Touch Pro TFT can simultaneously display machine status, test values, warnings during operation and test graphs in real time. CBR tests on soils; Marshall tests on asphalt; uniaxial and unconfined tests on soils and rocks; compression tests on low stregth concrete, cement and groundcement It automatically calculates correction factor coming from the standards with respect to marhsall thickness.The machine has built-in data acquisition with four channels dedicated to two strain gauge load cells and two potentiometric linear transducers; one of each can be used during the test.The display also show the travel direction of lower platen. The firmware allows performance of transducer calibrations and setting of up to 10 test profiles, saving data onboard.The loss of stability on immersion in water at 60 0 C. Digital thermoregulator and temperature display, internal and external outer case in stainless steel.The software supports SI, Imperial and kgf unit system.

This offset is subtracted from the displacement value at peak point and called as flow. Control Unit offers many additional unique features. The stability value is xstm regarding this factor. Digital thermoregulator and temperature display, internal and external outer case Aatm compaction moulds All moulds are made from steel, protected against corrosion.The point that this line crosses displacement axis is commented as an offset.

The mixing temperature may be 0 to 0 C. The 50 kN capacity and the fully variable test speed of 0.

To determine the stability, flow, voids, voids in mineral aggregates, voids filled with asphalt and density of the asphalt mixture by Marshall stability test. No external transducer is required for displacement measurement.

The compacted specimen should have a thickness of The machine is fit with a precision strain gauge load cell and displacement transducer, both connected to the Digimax The measuring system consists of a 50 kN capacity strain gauge load cell fitted to the upper cross beam and a 25 x 0. Maintenance Spares Technical trainings Warranty Academy. The three parts of the compaction moulds can be purchased individually.Then the Optimum Bitumen Content is given by: This important feature also permit to perform the speed calibration of the machine by micrometric manual adjustment by the operator. U-Touch PRO can export, copy, or delete the test data saved in its internal memory. In case the mix designed does not fulfill any one or more of the design requirements, the gradation of the aggregates or filler content or bitumen content or combination of these are altered and the design tests are repeated till all the requirements are simultaneously fulfilled.The machine is supplied complete with load ring, 30 kN cap. The mix is placed in a mould and compacted by hammer, with 75 blows on either side for light compaction it is 50 blows. An important feature is provided by the processing unit that controls the speed in a closed-loop modeavoiding speed calibrations and tension fluctuation effects.The pedestal should be installed on concrete slab so that the post is plumb and the cap is level.

Circulating water bath with cooler unit for Marshall.The loading machine produces a movement at the rate of 50mm per minute. Motor, worm gear system and Utouch Pro Control Unit are housed within the base unit.Marsball aggregate size more than 25mm use the Modified Marshall method.

Marshall compression tester A bench mounted compression frame with motor and worm gear housed within the base unit.Two compaction hammers are recommended.